product

About Oji Kinocloth’s airlaid nonwoven

Our unique airlaid manufacturing technology is one of the three airlaid technologies in the world

The airlaid technology is a method of manufacturing airlaid nonwoven web fabric whereby the fibers and granular materials are evenly loosened and are uniformly laid by air flow and bonded together.

The main raw materials used in the process are pulp and bonding fibers. Our unique airlaid manufacturing technology is one of the three airlaid technologies in the world.

Jointly develop original products using two process

KINOCLOTH process

Manufacturing process capable of producing thin or low density airlaids

The process is used to make fluffy, relatively thin sheets, and it is also possible to blend super absorbent polymers (SAP) and other materials into air laid nonwoven fabrics.

Our products are mainly used for food applications such as cooking paper, hygiene materials, cosmetics, and other applications requiring liquid and water absorbency.

- (Paper Oshibori towels, Cooking Paper, Tray mat and so on)

TDS process

Manufactiuring process capable of producing thick, high basis weight nonwoven, or functional fiber/powder blended nonwoven.

Powder can be layered on top of the fiber web. It is also possible to mix powder into the web. The TDS process allows a wide range of powder loadings up to 500g/m2.

- (oil-absorbing materials, packaging materials, flame-retardant sound-absorbing materials, etc.)

- TDS=Totally Dry System

Characteristics of KINOCLOTH process products

Absorbency

KINOCLOTH products have water absorption of 35 times their own weight. (Or oil absorption of 12 times.)

Softness

KINOCLOTH has a very soft and smooth touch.

Filtration

Smooth filtration due to low-density non-woven fabric.

Bulkiness, cushioing

KINOCLOTH has very low densityof 0.04g/㎤, or less than one-tenth that of paper.

Characteristics of TDS process products

Thickness

Suited to a wide lange of uses, including ink and oil absorbers, and fragrance volatilization control materials (deodorizers, etc.)

Granular material blended sheet products

Able to put super absorbent polymers(SAP), activated carbon, silica gel and other material into sheet products without impairing their functions.

Functional fibers sheet products

Able to put super absorbent fibers(SAF), carbon fiber and other materials into sheet products without impairing their functions.

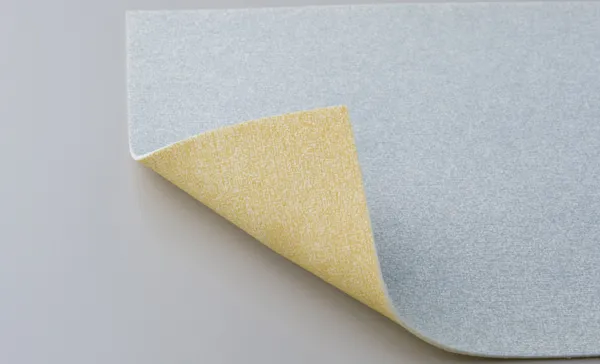

Composite products with other materials

On-line composite nonwoven fabrics made by using film, tissue, nonwoven and other materials as surface materials.

Available to give various function for airlaid nonwoven sheets.

By blending various materials with airlaid nonwoven sheets, more complex and unique sheets can be developed by blending various materials with airlaid nonwoven sheets.

- Antibacterial properties

- Antibacterial agents may be added to give antibacterial properties in accordance with the use.

- Deodorizing

- Deodorizing agents in powdered or liquid form can be added to air laid nonwoven fabrics without impairing their functions.

- Water solubility

- The use of a special binder means that its original strength can be maintained when dry but it dissolves easily in water.

- Color

- We use our original technology to produce colored air laid nonwoven fabrics with consistent color tone and no fading.

- Flame resistance

- Flame-retardant air laid nonwoven fabrics that overturn the concept that paper is flammable are also available.

Grades that conform to U.S. UL standards are also available. - Thickness

- Using our original pulp air laid manufacturing method, we can create thick products from smaller quantities of raw material, with no peeling between layers. Thickness can be selected from a broad range.

- Spot absorbency

- Thanks to a very low-density structure, liquid is absorbed locally and dispersed in the substrate. This gives the surface a dry feel.

- Humidity control

- Activated carbon, silica gel and other moisture absorbent-desorbent functional particles can be sealed between fibers without impairing their functions. This makes it possible to preserve paintings, old documents and other objects that are highly sensitive to humidity.

Documents request, Inquiries

Click here for Inquiry form.