process

KINOCLOTH process

Products list of KINOCLOTH process

Introduce four types of seats that can be produced using the KINOCLOTH process. Our unique airlaid method allows us to produce products that use pulp as the main raw material, which has the highest absorbency and is the cheapest.

KINOCLOTH Excellent absorbency, For cooking paper, paper oshibori towels, etc.

Airlaid nonwoven mainly made of pulp fiber which has high absorption in fibers

Characteristics

- Manufactured by using our own unique airlaid technology

- Made of 100% wood pulp bonded with special binders.

- Excellent absorbency, filtration, bulkiness and cushioning properties.

- Can be further augmented with antubacterial properties, water solubility, flame resistance and other functions.

Basic structure

Function

Products example

- Cooking paper

- Paper oshibori towels

- Absorbent materials for sanitary products

- Medical sheets

- Wet wipe

- Nursing dry sheets

- Seeding sursery sheet for hydroponic cultivation

PALCLOTH Excellent strength and flexibility. For face masks, tray mats, etc.

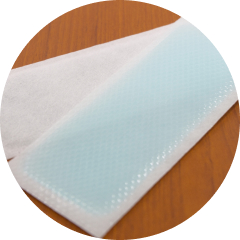

Airlaid nonwoven made with rayon on the surface layer.

Characteristics

- Made with a layer of rayon on one or both sides of KINOCLOTH process products.

- Superior strength, surface smoothness and softness compared to KINOCLOTH process products.

- Applications include cosmetic facemasks, cosmetic puffs and tray-mat.

Basic structure

Characteristics

Products example

- Tray-mat

- Dry wipe

- Cosmetic facemasks

- Cosmetic puff

- Medical sheets

B・SAP Water absorption and sagging resistance. For thin napkins, paper diapers, etc.

Airlaid nonwoven made with intermediate layer of super absorbent polymer (SAP)

Characteristics

- Made eith intermediate layer of super absorbent polymer blended with PALCLOTH. (Can also be blended with KINOCLOTH and HI-CLOTH.)

- Excellent water absorbency and twist resistance.

- Applications include thin napkins, incontinence pads and paper diapers.

Basic structure

Function

Products example

- Absorbent materials for sanitary products

- Diapers, Incontinence products

- Portable toilet absorbent sheets

- Neck cooling sheet

HI-CLOTH Stable shape x increased strength. For sweat-absorbing sheets, seedling-raising sheets, etc.

Airlaid nonwovens made with synthetic fiber

Characteristics

- Superior shape stability compared to KINOCLOTH.

- Better wet or dry strength.

- Can produce high basis weight and thick products.

- Can change airlaid texture by using different fibers.

Basic structure

Function

Products example

- Absorbent materials for sanitary products

- Dry wipe

- Wet wipe

- Seeding sursery sheet for hydroponic cultivation

- Nursing dry sheets

Powder Formulation Methods

KINOCLOTH process allows powder to be blended between webs.

Even thin sheets can be given functions.

Sheets blended with super absorbent polymer (SAP) are marketed under the name "B-SAP," mainly for sanitary material applications.

Fine particle size powder can be mixed with binder and adhered to sheets.

Depending on the powder, we may not be able to provide this service. Please contact us for details.

We can process sheets according to your needs

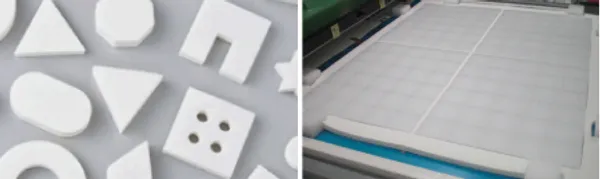

Punching / Cutting

Various types of raw materials can be die-cut into complex shapes. We can also perform cutting processing from complex shapes to flat sheets to meet a wide variety of needs.

Various chemical volatilizers, oil absorbents, evaporation and humidification materials, electrical components, filters, etc.

Embossing

Various embossed shapes are available to further improve the cushioning and cosmetic properties of the base material.

Various chemical volatilizers, agricultural materials, etc.

Laminating

Composites with non-woven fabrics, films, etc. using hot-melt laminating machines. Laminate processing is also available.

Various sheets, packaging materials, absorbent materials, etc.

Documents request, Inquiries

Click here for Inquiry form.