process

TDS process

Products list of TDS process

Introducing three types of sheets that can be produced by the TDS (Totally Dry System) process.

This is the only process in the world that does not use water and does not lose the original performance of the material.

The TDS process is the only process in the world that does not use water, and can produce sheets using a wide variety of raw materials and a wide range of materials without losing the original performance of the materials.

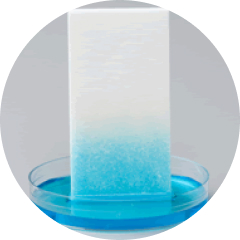

HATOSHEET Excellent liquid absorbensu and sound absorbensy. Oil absorption sheet ,

Flat sheet offering free configuration of thickness and hardness.

Characteristics

- Sheet in thickness from 1mm through 40mm, made from pulp as the mainraw material.

- Excellent liquid absorbency, retention, diffusion and volatillzation, and sound absorbency.

- Can be blended with granular or fnctional fibers, or used with other materials to make composite products.

Products example

- Oil absorption sheet

- Press forming process sheet

- Liquid air fresher volatitization material

- Waste fluid absorbents

- Civil engineering. Absorbent sheet (concrete repair etc.)

- Humidifers

- Transpiration materials

SOFTSHEET Soft and impact-resistant. Used as cushioning material, freshness-retaining material, etc.

Rolled sheet offering excellent softness.

Characteristics

- Excellent softness, cushioning and absorbency.

- Can be blended with granular material or functinal fibers.

- Applications include cushioning, maintaining freshness, cosmetic puff and industrial components.

Products example

- Sheets for Cryopreservation

- Sheets for dead bodies

- Cosmetic clensing sheet

- Bodily fluid absorbent sheet

- Cushioning material

- Sheet for maintaining freshness for shrinps

- Sheet for maintaining freshness for agricultural products

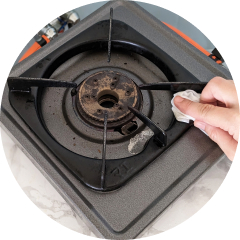

MICLOTH Can be combined with other materials. For filters, evaporation, humidification materials, etc.

Sheet made principally of synthetic fibers

Characteristics

- Excellent filtration, scraping and cushioning properties.

- Can be blended with granular material or functional fibers, or usedwith other materials to make composite products.

- Applications include fibers. Wipes consumer goods and electrical components.

Products example

- Scraper sheets

- Wipes

- Water purifying filters

- Oil filters,

Cabin Filters

Powder Formulation Methods

In the TDS process, powders can be stacked on top of the web.

It is also possible to mix the powder into the web.

Possible powder mixing volume with the TDS process is about 340 g/m2.

※Please feel free to contact us as it depends on the type of powder and sheet composition.

※Depending on the powder, we may not be able to provide this service. Please contact us for details.

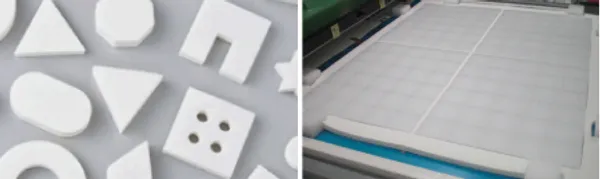

We can process sheets according to your needs

Punching / Cutting

Various types of raw materials can be die-cut into complex shapes. We can also perform cutting processing from complex shapes to flat sheets to meet a wide variety of needs.

Various chemical volatilizers, oil absorbents, evaporation and humidification materials, electrical components, filters, etc.

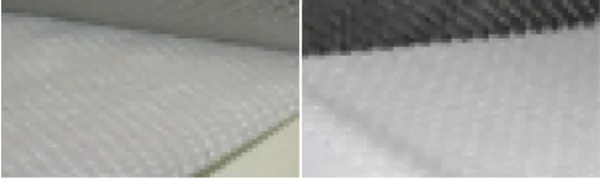

Embossing

Various embossed shapes are available to further improve the cushioning and cosmetic properties of the base material.

Various chemical volatilizers, agricultural materials, etc.

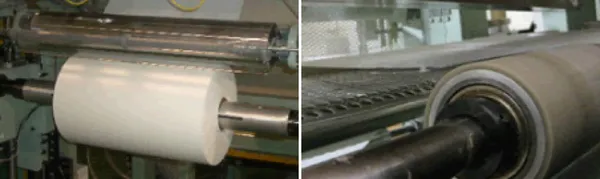

Laminating

Composites with non-woven fabrics, films, etc. using hot-melt laminating machines. Laminate processing is also available.

Various sheets, packaging materials, absorbent materials, etc.

Molding process

Nonwoven fabrics made from 100% biomass are formed by stamping molding and resin sheet molding machines.

Products related to "KATACHI-SHEET," an environmentally friendly package, etc.

Documents request, Inquiries

Click here for Inquiry form.